Hejian Hengji Bit Manufacture Co.,Ltd is located in Hejian,Hebei province.and is Chinese bit industry's emerging enterprises.The company is mainly engaged in the development of various series of bits, development, production and sales.

Hengji company has developed and mass-produced products 3 inches to 26 inches series steel tooth bit and tricone bit, various types of PDC bits, core bit and production and processing assembly 0.6 m to 3 m large diameter drill bits.Widely used in the oil, natural gas, hydrology, address, ore drilling engineering, product marketing the country and 20 countries and regions in the world.

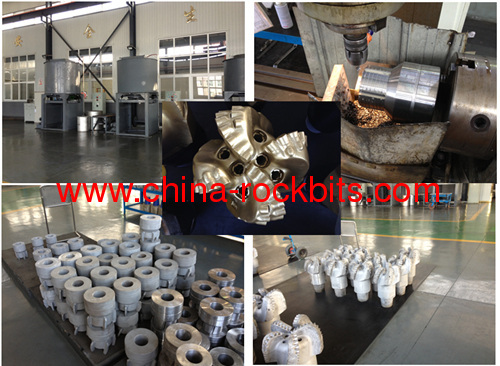

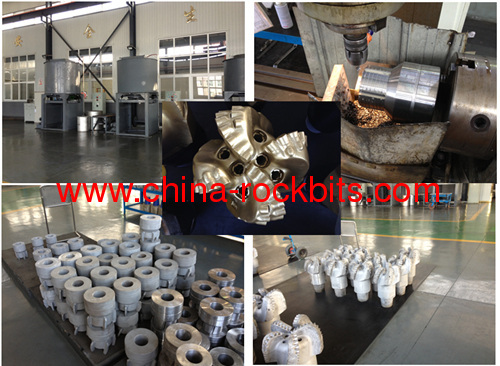

Hengji company keeps track of the international advanced technology, and built a flexible production line of CNC machining centers mainly drill bits, established a perfect quality assurance system, widely used in the production and management of computer application systems and control systems.

Hengji various drill bits, to ensure full compliance with all the terms and standards of the American Petroleum Institute API specification, design, manufacturing and production, and to ensure full compliance with the the API specification requirements and content.

"Hengji bit, focusing on quality" Hengji always follow with "high quality products and services users "philosophy, adhere to the leading design highlights the quality, state-of-the-art technology to promote quality, perfect management ensure quality. Henderson produced drill products continues to lead the domestic industry, expanding the international market, providing quality products to the worldwide drilling industry.

Part ll.Operation Instructions on Hengji Tricone bit

1.Please select the applicable formation and parameters according to the instructions.

2.Selection of the appropriate nozzle according to the hydraulic parameters of the nozzle hole size differential is not too much to prevent erosion of the stream channel.

3.Before the bit running into the well, the user should carefully check the overall appearance and confirm that the serial number on the shank end is the same as those on the packing box and certificate.

4..The required bit operating procedures should be followed. After getting to the bottom hole, the bit must be running in slowly with lighter bit weight(WOB: 5-15KN, RPM: 60r/min) for 1/2 hour and then drilling ahead with normal WOB.

5.If abnormal damage(s) of the bit occurred, please contact the company and the packing box, inspection certificate, original performance records as well as the failure bit(with nozzles on ) should be kept for our view, or we are not responsible for it.

Part lll.Packing and delivery

Packing: wooden case or as your requirements

Delivery: depend on the contract

Last part.The advantages of our products.

Last part.The advantages of our products.

1.Reasonable price,durable

2.adapt to the soft, medium and hard of various strata

3High-strength, high flexibility,, high wear resistance

4.Optimal hydraulic design,easy to move out the drill cuttings and cooling.

5..Equipped with back reaming teeth.

6.The cutter is high performance to increase the ability of anti-impact and anti-abrasive.

most importantly, Our company is specialized in producing all kinds of tri-cone bits in large quantities for many years. They are of good quality and have sophisticated technology. and our engineers and work team have professional knowledge and rich experience to satisfy your interests.